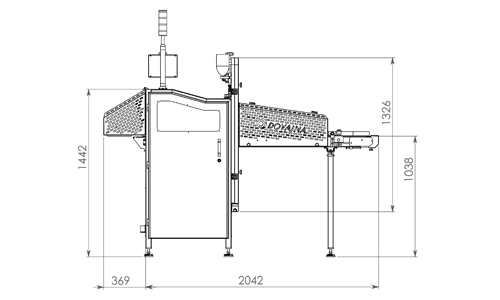

ADPP round bread slicer in halves

ADPP – industrial equipment for medium and large bakeries. Slicer and turner, as a single integrated device is made for slicing round (black and white) bread in halves and rotating them by 90 degrees after. The equipment is manufactured according to all safety requirements and complies with the European Parliament and Council Directive regulations.

Cooled bread is placed on the conveyor and moved forward towards the band saw, where it is cut in half into two equal parts. The sliced product stops at its default location and is rotated by 90 degrees. The rotated product travels to the vertical slicer DP-4-2M, where the bread halves are cut into slices. Sliced bread, with the help of the operator, is pushed into bag and and moved towards the bag closing device.

Bag closing options: clip, tape, twist.

Product

Round bread

Diameter of product

from 200 to 220 mm

Height of product

from 60 to 80 mm

Capacity

12-15 pcs. / min

Power input

1,5 kW, 4A

Power supply

3 x 400 V, 50/60 Hz

Fully-automaTIc lines |

VollautomaTIsche Linien

VollautomaTIsche Linien

Download brochure (PDF)

DOWNLOAD

Equipment produced by:

UAB Dovaina

Contact Us

Lehrmann GmbH

Bramfelder Strasse 102 A

DE-22305 Hamburg

Germany

Bramfelder Strasse 102 A

DE-22305 Hamburg

Germany

P +49 (0) 40 577 09 091

F +49 (0) 40 577 09 092

info@lehrmanngmbh.de

F +49 (0) 40 577 09 092

info@lehrmanngmbh.de

You are welcome to write, call and visit us. We will be pleased to advise you.